Maintenance

Providing Approved Maintenance Organisations and Engineers with Foreign Object Damage (FOD) solutions.

Aviation Maintenance

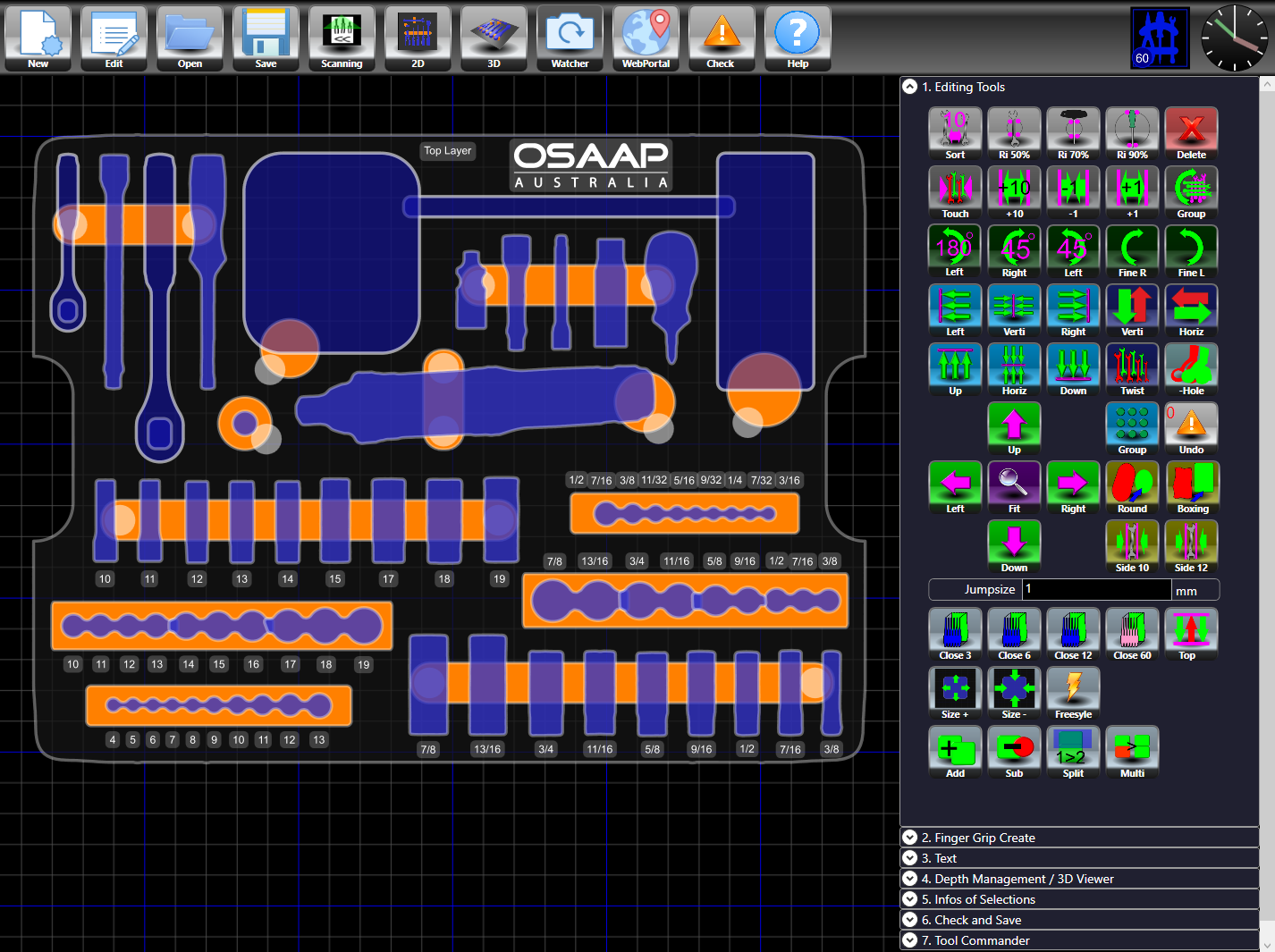

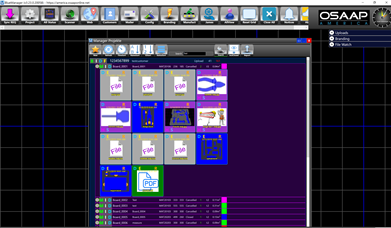

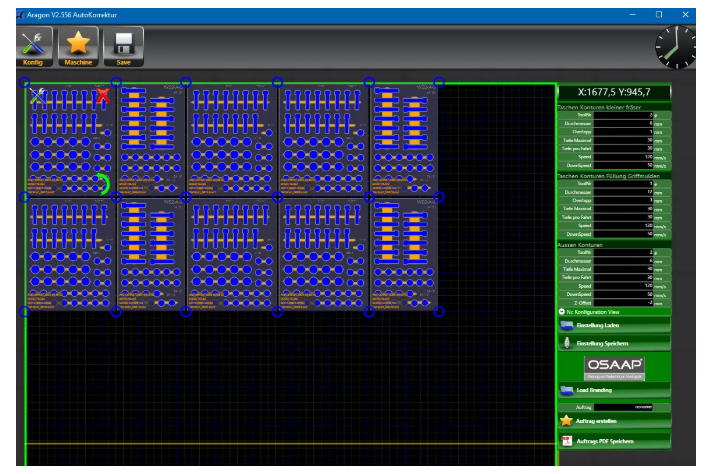

Aviation maintenance is both a time and safety-sensitive process, especially in aircraft on ground (AOG) situations. Maintenance personnel need to complete work quickly and accurately. Effective tool control in aviation maintenance is a necessary practice to ensure ongoing aircraft airworthiness. The ability to rapidly identify missing tooling in a safety-sensitive environment combines responsibility and accountability. Utilizing 5S methodology and shadow boards enables streamlined maintenance operations, which gets aircrafts back to flying condition in a shorter amount of time, without compromising quality of work.

Understanding 5S

One of the biggest competitive advantages that any repair or maintenance service can have, is eliminating waste. Waste refers to much more than wear-and-tear or replacement of damaged tools; it refers to all actions and resources that are not value-added or required. 5S organization and shadow boards for aviation maintenance can help AMOs and FBOs decrease waste by reducing time spent on non-essential activities.

Proper tool organization has the greatest effect on wasted motion, therefore decreasing wasted time. Wasted motion refers to any action that does not directly contribute to job completion. While the amount of wasted time is highly variable due to differences in facility size, tooling procedures, and workforce, many MROs and FBOs find that searching for tools can add nearly an hour of time to aviation maintenance.

Shadow Board Effects on Time Reduction

Unsure how much time searching for tools actually takes? Observe AMO’s performing maintenance processes, and note how often progress was stalled to find the right tool. Shadow boards for aviation maintenance eliminate the time spent searching for tools by providing a designated space for tooling, with a system that is simple, sustainable, visual, and free of guesswork.

Shadow boards can also be conveniently placed on tool crib walls, in high-traffic areas on the hangar, or in each AMTs tool chest.

Sort, Set, Sustain

Shadow boards are clearly aligned with 3 of the 5 key principles of the 5S methodology: sort, set, and sustain.

Sort: Shadow boards eliminate clutter by only including space for necessary tools and equipment, and leaving no room to place additional items.

Set: “A place for everything and everything in its place” is the motto. By “setting” a place for tools and equipment, each item has a designated location, eliminating the need for maintenance personnel to waste time searching.

Sustain: Shadow boards create an easily sustainable system and process for AMO’s to continue using.