Process

Order and Cleanliness at the Workplace

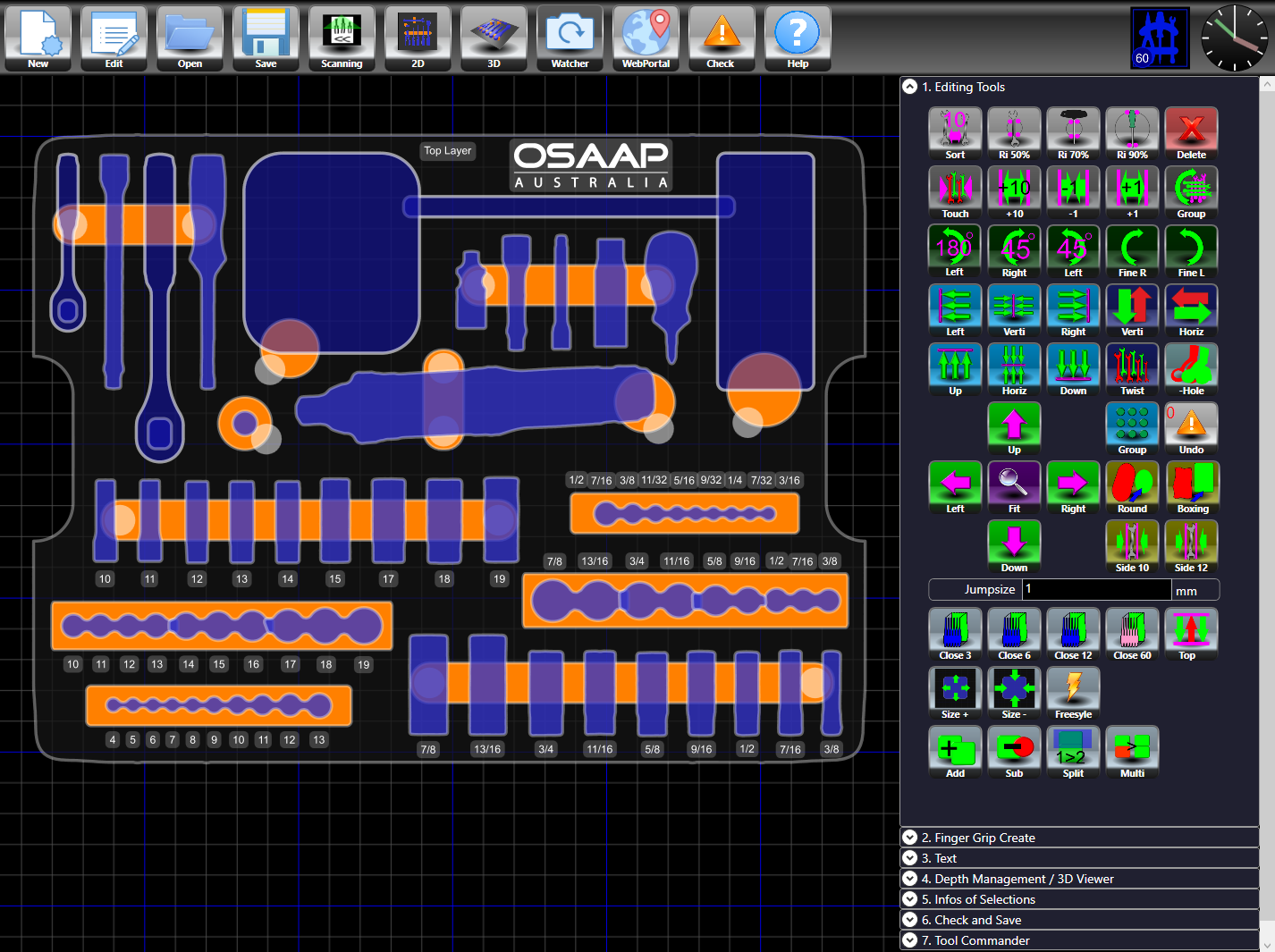

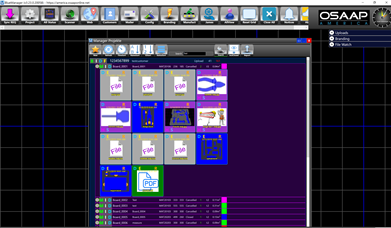

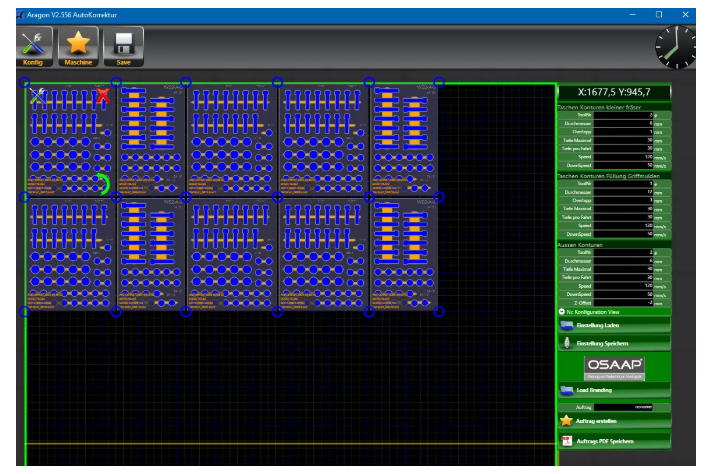

We’re a custom-fit, full-solution process. And we go beyond all requirements to make the custom tool inserts that will work for you. For every project, every time. No matter what equipment you have, expect the highest quality–and not to mention, fastest–shadow boards through our proven and precise process. But that doesn’t mean we’re not collaborative. Within our customer interface, every client can be involved in as many steps of the process as they choose–from taking perfect photos of their tools, to the design process in our easy-to-use custom CAD software. From day one of production, your project is under control. And we mean precision-control. We generate instant and unique NC codes to create a shadow board of any size with any tool combination. Best of all, we rely on state-of-the-art manufacturing processes paired with our proprietary software to create the perfect space for each individual tool.

Workflow

We’re a custom fit, full-solution process.

Read MoreFree Design

About 50% of our customers want full design control and as a result do their own design with our software. The other 50% of our customers take advantage of our free design service.

Read MoreKitting

Every tool needs its exact right place.

Read MoreCustom

OSAAP Australia stocks and constructs our Shadow Boards from the purest polyethylene foam manufactured.

Custom