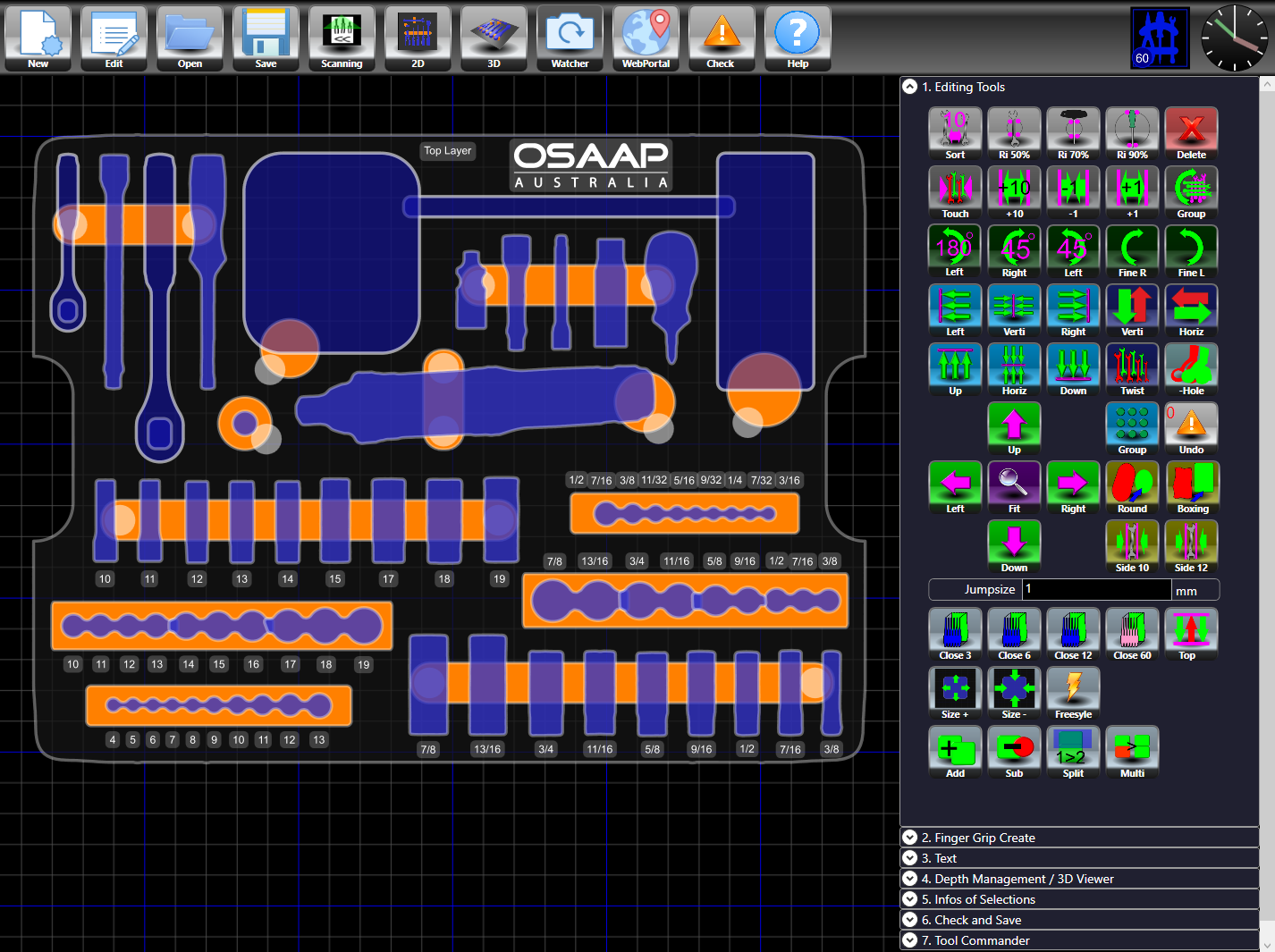

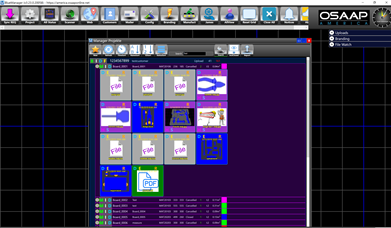

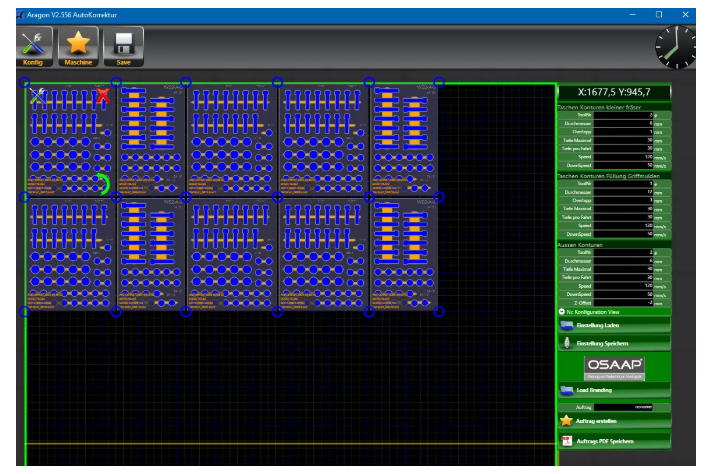

Materials

OSAAP Australia stocks and constructs our shadow boards from the purest polyethylene foam manufactured. Below is more information on the foam and its characteristics.

Standard Foam

OSAAP Australia exclusively uses Zotefoam products because they are the purest polyethylene foam manufactured in the world today.

AZOTE is the group brand name for Zotefoam’s closed-cell, cross-linked polyolefin foam. It is high quality foam from differing base polymers that are all manufactured using the same unique nitrogen expansion process route. You can find a more detailed description of our proprietary manufacturing processes if you click the link below. AZOTE was formerly used as a name for Nitrogen and is still used by French chemists to refer to the element. AZOTE foam derives many of their exceptional properties directly from the use of this inert, tasteless, odorless gas in the manufacturing process.

We use Zotefoams’ Plastazote® family of products. Plastazote foam is engineered to offer superior performance and lighter weight. The absence of any chemical agents in the foam and a consistency of cell structure and density allows Zotefoam to offer the world’s lightest cross-linked foam. The lack of any chemical agents allows Plastazote to withstand destructive materials such at Skydrol which is used throughout the aerospace industry.

Our standard foam for Industrial applications is Zotefoam LD45 which is a closed cell/cross linked polyethylene foam. We stock material with a 3mm to 5mm black top layer and a colored bottom layer: Blue, Red, Green, Yellow, and Grey. These combinations are stocked in 30mm, 60mm and 90mm thickness.

Zotefoam is closed cell and cross linked polyethylene foam: This means the material does not absorb moisture and can be cleaned in a part cleaner or with aggressive solvents.

“What impressed me the most about the design process was OSAAP’s ability to come up with a design extremely fast; literally went from concept to prototype in 3 days (came in with idea on Friday and left with samples that following Monday!)”

Michael Jansen – Principal Manufacturing Engineer

“When the finished shadow boards arrived at the office our team was blown away! It is far superior to the previous die cut and laminated foam inserts that were being used previously and fail within months of normal use. The quality and precision of the foam Is incomparable to anything we have seen before. The foam is robust, and the color options are a great touch to match your company colors or for additional organization.”

Mike Letchworth – High Voltage Battery Test Engineer

Sample Request

Foam Accessories

View the additional accessories you can add onto your foam shadowboards.