Blue Imager 3D

OBi3

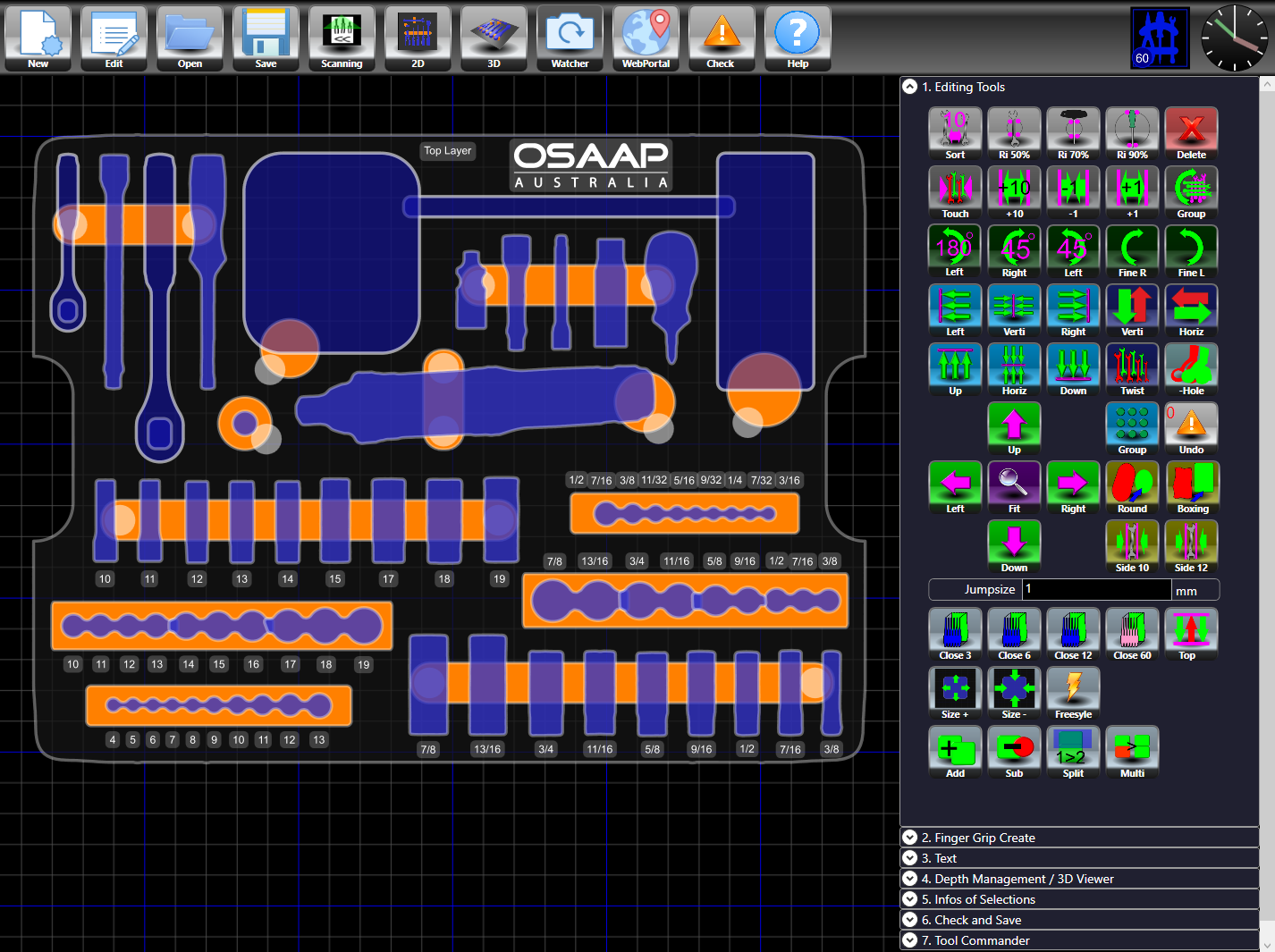

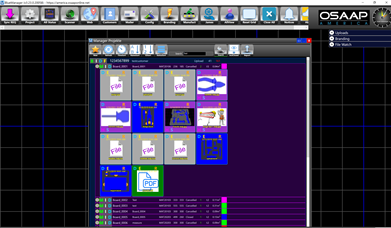

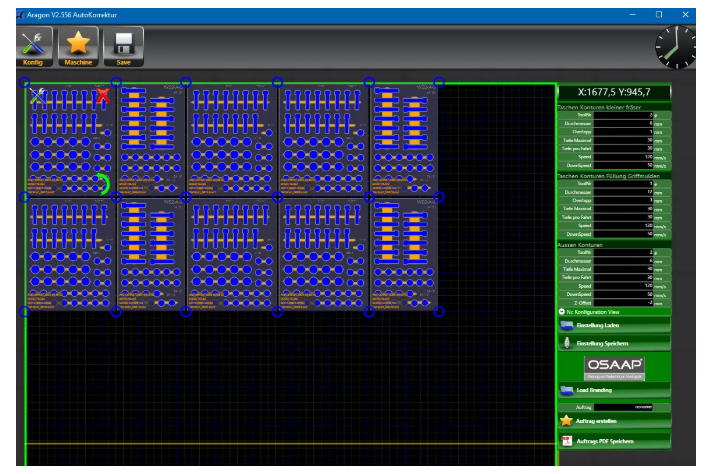

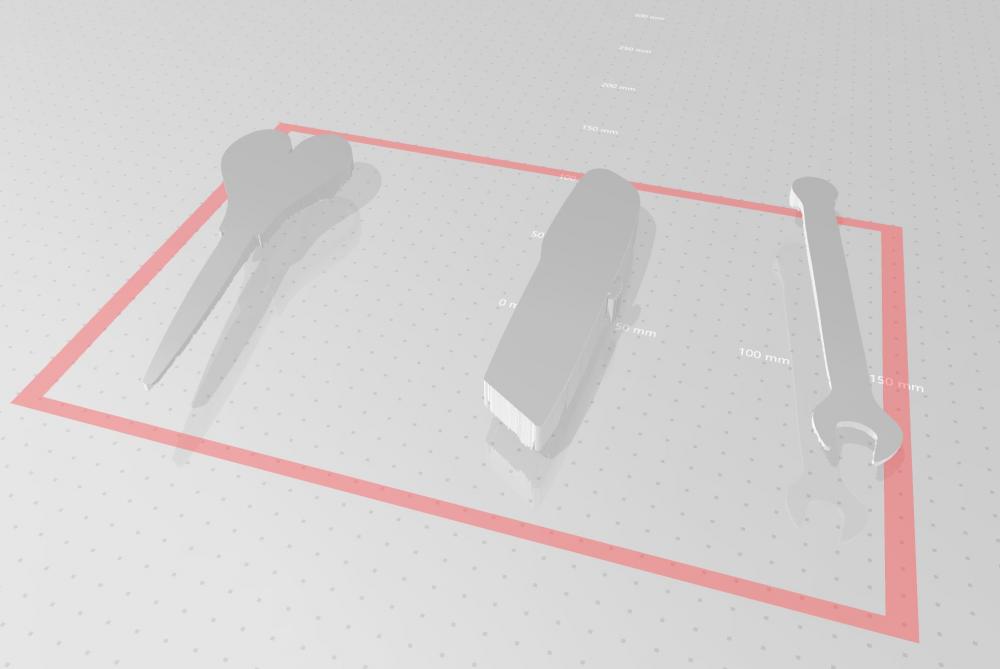

The OBi3 allows the user to acquire the 2D shape and topography of the upper surface of tools placed on it’s measuring surface. This information can be used to create a foam insert which precisely matches the 2D shape and 3D contour of your parts. The system uses a high-speed industrial camera and backlight to acquire the 2D shape of the part. A DLP projector is then used to create a structured light scan of the parts’ 3D upper surface.

Details

> Measuring Area: approximately A1 [594 x 841mm]

> 2D measuring speed: approximately 10 seconds for a typical part/scan

> 3D measuring speed: approximately 1 minute for a typical part/scan

> Number of measurements: up to 5 million per scan

> Optics: 5MP high-speed industrial camera

> Part Z height limitation: 225mm

> Accuracy: +/-0.1mm or less

> Frame: Sheet metal shrouded enclosure

OBi3 Operator Tutorial

Other Light Station Solutions

View our assortment of light stations and tool-capturing applications.