From Concept to Creation: Bruce Roffey’s Strategy for Sustainable Custom Solutions at OSAAP Australia

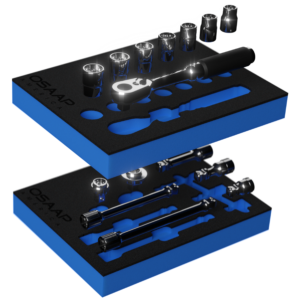

In industries where organisation, safety, and efficiency are crucial—like aviation, aerospace, defence, and maintenance— OSAAP Australia delivers tailored solutions for tool control, asset management, and equipment protection. As a leading provider of custom foam solutions, we specialise in designing and producing precision-engineered foam inserts and shadow boards that improve operational effectiveness and safety.

Bruce Roffey, OSAAP Australia’s new business manager, shared with us his take on the industry needs and how he sees OSAAP supporting those critical industries in the future.

Using Shadow Boards and Foam Inserts for Expensive Tools

Bruce highlights the significant role OSAAP’s shadow boards play in streamlining workflows across various industries.

“Our shadow boards aren’t just about organisation; they are about making everyday tasks easier and more efficient,” Bruce says. “When every tool has its own spot, it means less time wasted hunting for what you need and more time getting the job done.“

This is especially important in industries like aviation, defence and maintenance, where every second counts. “In these fields, having tools readily accessible not only keeps things running smoothly but also reduces the chance of delays,” Bruce explains. “And by keeping workspaces tidy, we are also contributing to a safer environment. Fewer tools left lying around means fewer accidents, which is something everyone can appreciate, especially in high-risk areas like aerospace and defence.”

Bruce points out that “In these industries, tools and assets are often very expensive, so losing or misplacing them can be costly. Our shadow boards help keep everything in its place, preventing delays and reducing the need to replace tools.” He adds, “The design makes it easy to see when something’s missing, which helps keep things running smoothly and efficiently.”

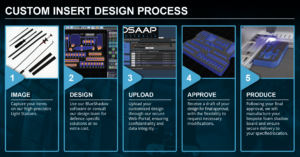

Our Design Process: How We Make It Happen

OSAAP Australia has developed an easy-to-follow process for businesses looking to create custom shadow boards. Bruce Roffey, our new business manager, shares insights into how this process works.

- Design: “We start by having customers arrange their tools on a light panel and capture a high-resolution image,” Bruce explains. “This image is the starting point for designing the shadow board.“

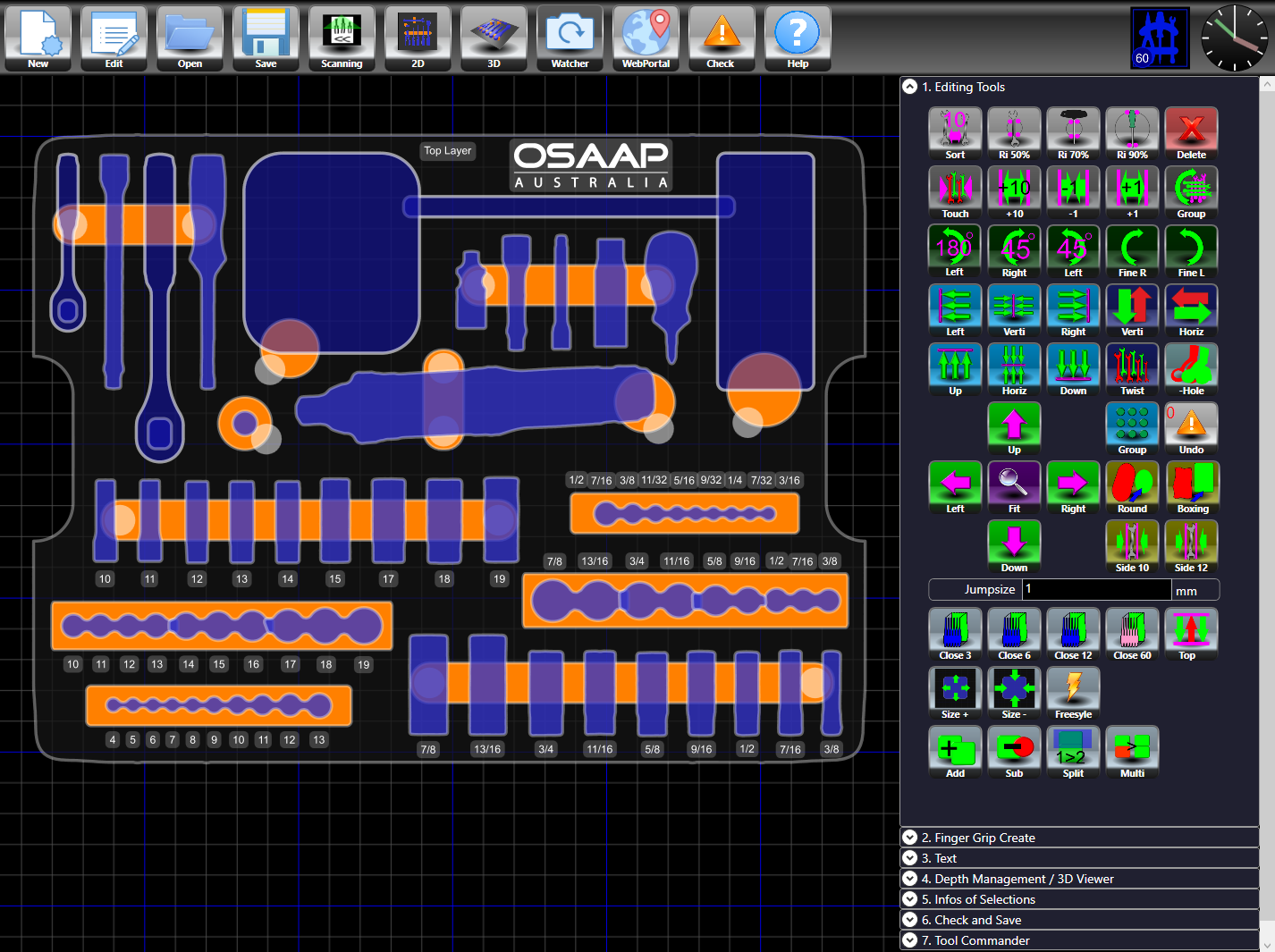

- Customisation: “With our free Blue Shadow CAD Software, users can design their board just the way they need it,” Bruce says. “They can choose the thickness, colour, and size that works best for them.”

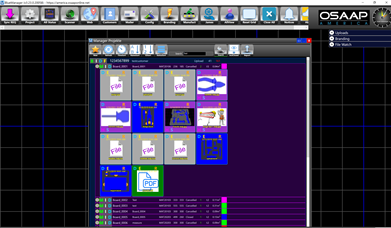

- Approval: “Once the design is ready, it’s submitted through our web portal for review and approval,” Bruce notes. “This step ensures that the final product meets the customer’s exact needs.”

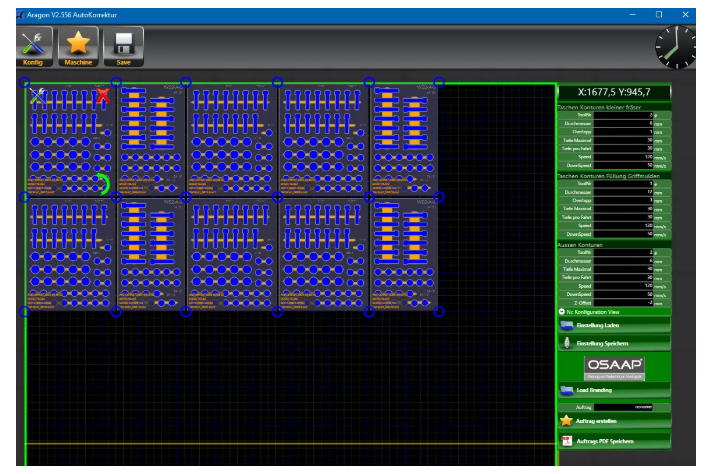

- Manufacturing: “Our automated production process then takes over, allowing us to efficiently produce one or multiple boards,” Bruce adds.

- Personalisation: “We can also add logos and custom text to the boards, making them unique to each business,” Bruce says.

By offering these tailored organisational solutions, OSAAP Australia is helping businesses across Australia improve their workflow, improve safety, and optimise their operations.

Strategic Partnerships for Greater Capabilities

OSAAP Australia’s recent partnership with Queensland Gaskets has been highly beneficial. “This partnership has expanded our product offerings and improved our manufacturing capabilities, allowing us to deliver even more customized solutions,” Bruce explains.

Bruce also highlights the advantages of being a platinum dealer for Pelican cases. Known for their durability and reliability, Pelican cases, combined with OSAAP’s custom foam inserts, offer unmatched protection for valuable tools. “The quality and custom fit provided by Pelican cases and our inserts are of the highest quality ensuring our clients’ tools or equipment are well-protected,” Bruce adds.

Current and Future Projects

Bruce shared a recent success that showcases OSAAP Australia’s capabilities. In a project for a government organisation, the team created custom foam inserts for Pelican cases to protect camera gear used in the field. The project also included laser etching for traceability and ID tracking numbers, demonstrating OSAAP’s expertise in delivering high-quality, tailored solutions.

“We are working on some exciting projects, including demo kits for an aviation company and a custom Milwaukee tool storage and transport solution for an agriculture customer,” Bruce shares.

These projects align with OSAAP’s vision of promoting lean manufacturing and efficient asset management, helping businesses save on costs.

Expanding into defence, medical and telecommunications

Looking ahead, OSAAP Australia is planning to expand into the defence, medical, and telecommunications industries. “With the rise of rural internet services like Starlink, there’s an increasing need for organised tool storage in service vehicles within telecommunications. In the medical field, we are focused on developing solutions for transporting sensitive equipment and ensuring proper asset control for high-value instruments,” says Bruce.

In the defence sector, OSAAP aims to create custom solutions to protect and organize sensitive equipment, from weapons to communication devices. These efforts are designed to enhance safety, efficiency, and reliability in defence operations, positioning OSAAP as a leader in these critical industries.

Easy Ordering with a Mobile App

Bruce is excited about the Blue Mobile app launch in Australia, set for the last quarter of 2024.

“This new app, developed by OSAAP America, will significantly improve how we manage shadow board projects and custom foam inserts. Blue Mobile offers a comprehensive set of project management features, allowing users to monitor all aspects of their projects from a single platform on their phone,” Bruce says.

The company is also exploring the potential of integrating IoT and Industry 4.0 technologies in future innovations. “We’re considering adding GPS tags to our foam inserts, though it’s still in the early stages,” Bruce mentions. This aligns with OSAAP Australia’s vision of becoming an industry leader in custom solutions by embracing advanced technologies.

Saving the environment by using off-cuts

Sustainability is a priority for OSAAP Australia. “We are exploring ways to reuse foam waste in our manufacturing processes or develop new products that utilize these off-cuts,” Bruce explains. The company also aims to build an Industry 4.0 factory, integrating advanced technologies to create a more efficient and sustainable manufacturing process.

“Our goal is to lead the industry in custom solutions and sustainable precision manufacturing,” Bruce continues. OSAAP is committed to supporting Australia’s manufacturing industry by boosting local production, reducing dependency on imports, and maintaining competitiveness in critical areas like aviation, aerospace, defence, and medical. By adopting advanced technologies and sustainable practices, OSAAP is ready to make a significant impact on the industry and contribute to the future of manufacturing in Australia.